XIAMEN SENGKEN INDUSTRY&TRADE CO.,LTD.

OEM Manufacturing Precision Cheap ABS PP PC Custom Plastic

Product Name :

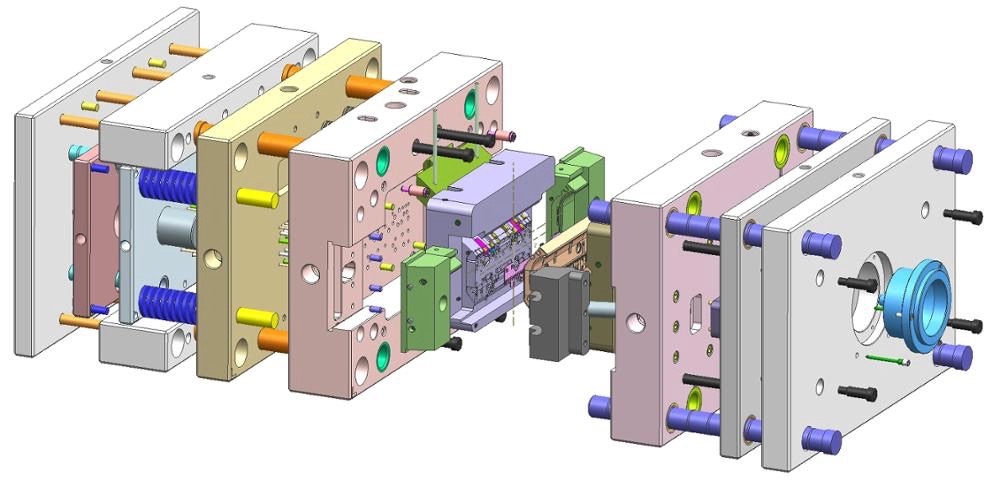

Plastic Molds Injection MoldsShaping Mode :

Plastic Injection MouldCore & Cavity Steel :

2316# steel, S136, H13,718,SKD61,P20,S50C,45#steel,4Cr13, 3Cr13, Becu or based on customer's requiretMould Base & Standard Component :

P20, 4cr13, h13Steel Hardness :

HRC30-35 for base material; HRC45-48 for core and cavity material; HRC60-62 for special parts materialMoud Precision :

+/-0.01mmCavity Number :

Single cavity, multi-cavity, and family mouldsRunner :

Hot Runner / Cold RunnerProduct Name: China Manufacturer Custom High Quality Plastic Auto Part Plastic Mould

Shaping Mode:Plastic Injection Mould

Core & Cavity Steel: 2316# steel, S136, H13,718,SKD61,P20,S50C,45#steel,4Cr13, 3Cr13, Becu or based on customer's requiret

Mould base & Standard Component: P20, 4cr13, h13

Steel Hardness: HRC30-35 for base material; HRC45-48 for core and cavity material; HRC60-62 for special parts material

Plastic Material: ABS/PP/POM/TPU/TPE/PC/PA6/PA66/PC+ABS/PA6+GF/HIPS/PE/PVC etc.

Moud Precision:+/-0.01mm

Cavity Number: Single cavity, multi-cavity, and family moulds

Runner: Hot Runner / Cold Runner

Injection System: Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc.

Equipment: CNC,EDM, 3d coordinate measuring instrument,Machine,plastic machinery,etc

Surface Treatment: Polishing,Painting,Chroming,Anodizing, Brushing, Silk Screening,Water Transfering, Laser Cutting,Leather Covering,Texture,Sanblasting,Gilding,UV Painting…

Ejector System: Unscrew by motor, stripper plate, ejector sleeve, ejector pin

Lead Time:

-Tooling: 10-45 days;

-Sample: 3 days;

-Production time : 10-30 days

Product Photos:

INSERT MOLDING:

Insert molding is a custom injection molding process that encapsulates components in a plastic part. It is commonly used for plastic injection molded parts with molded-in metal features, such at strengthening members and threaded inserts.

OVERMOLDING:

Overmolding is a unique injection molding process that combines two or more components together.It is the best practice for the plastic manufacturing of multicolor and multi-layers products.

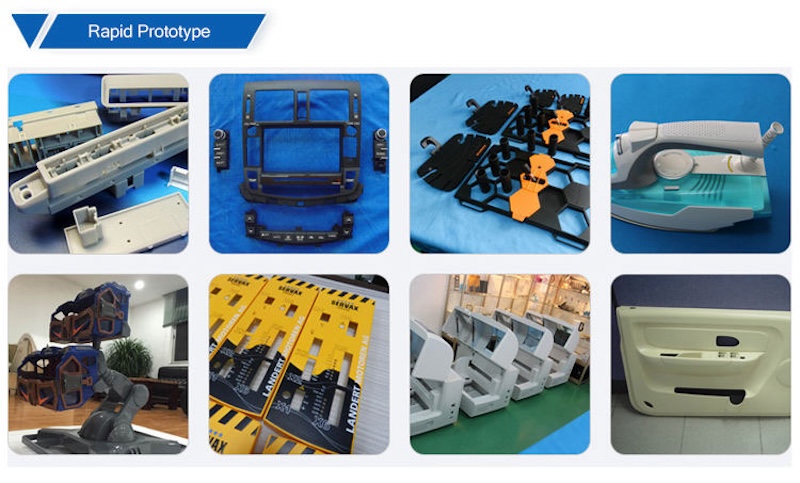

PROTOTYPE TOOLING:

Fast and cost-effective process to create aluminum or steel injection molds for quick turn injection molding.Ideal for rapid prototyping needs or validating product concept for production.

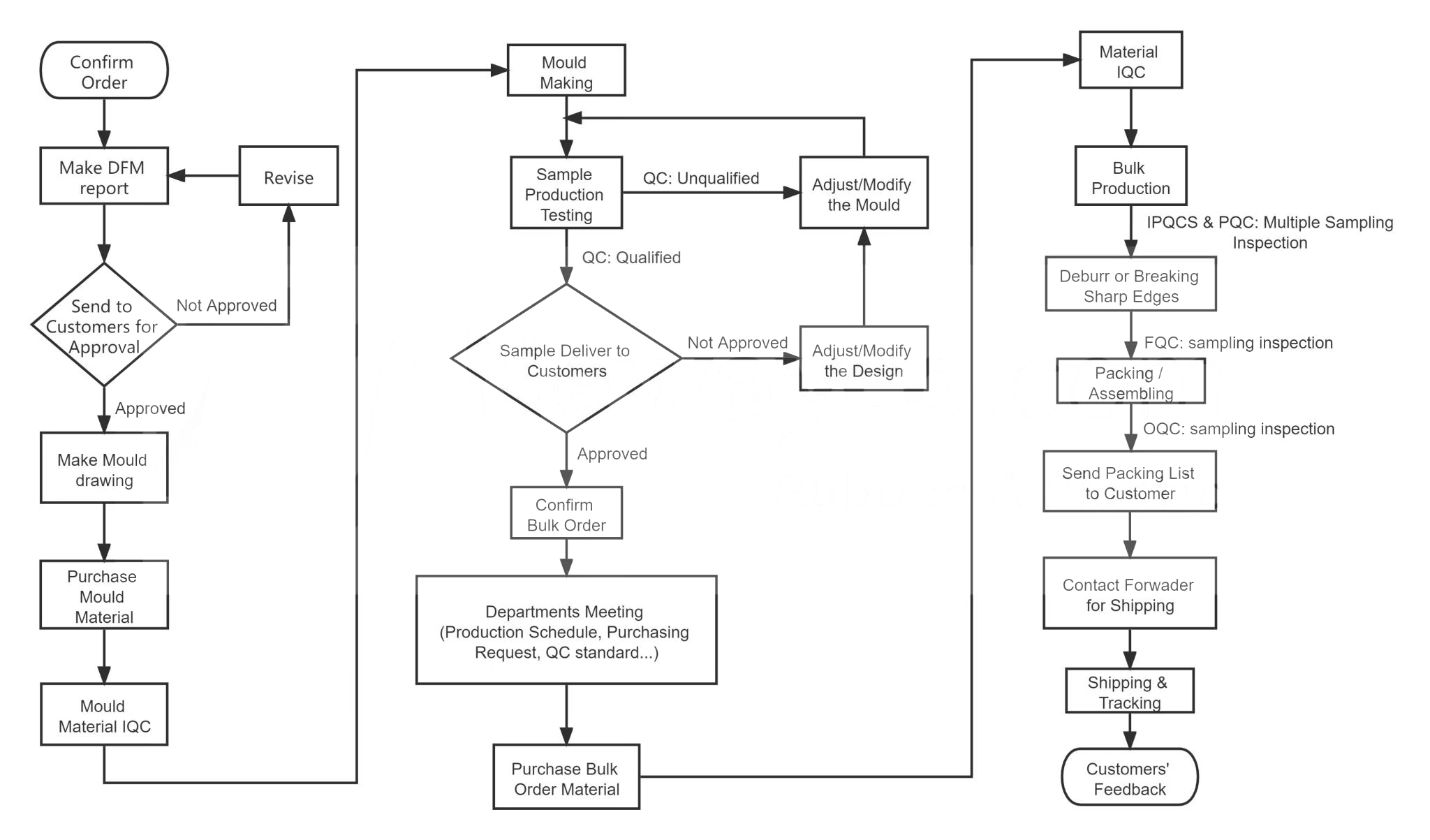

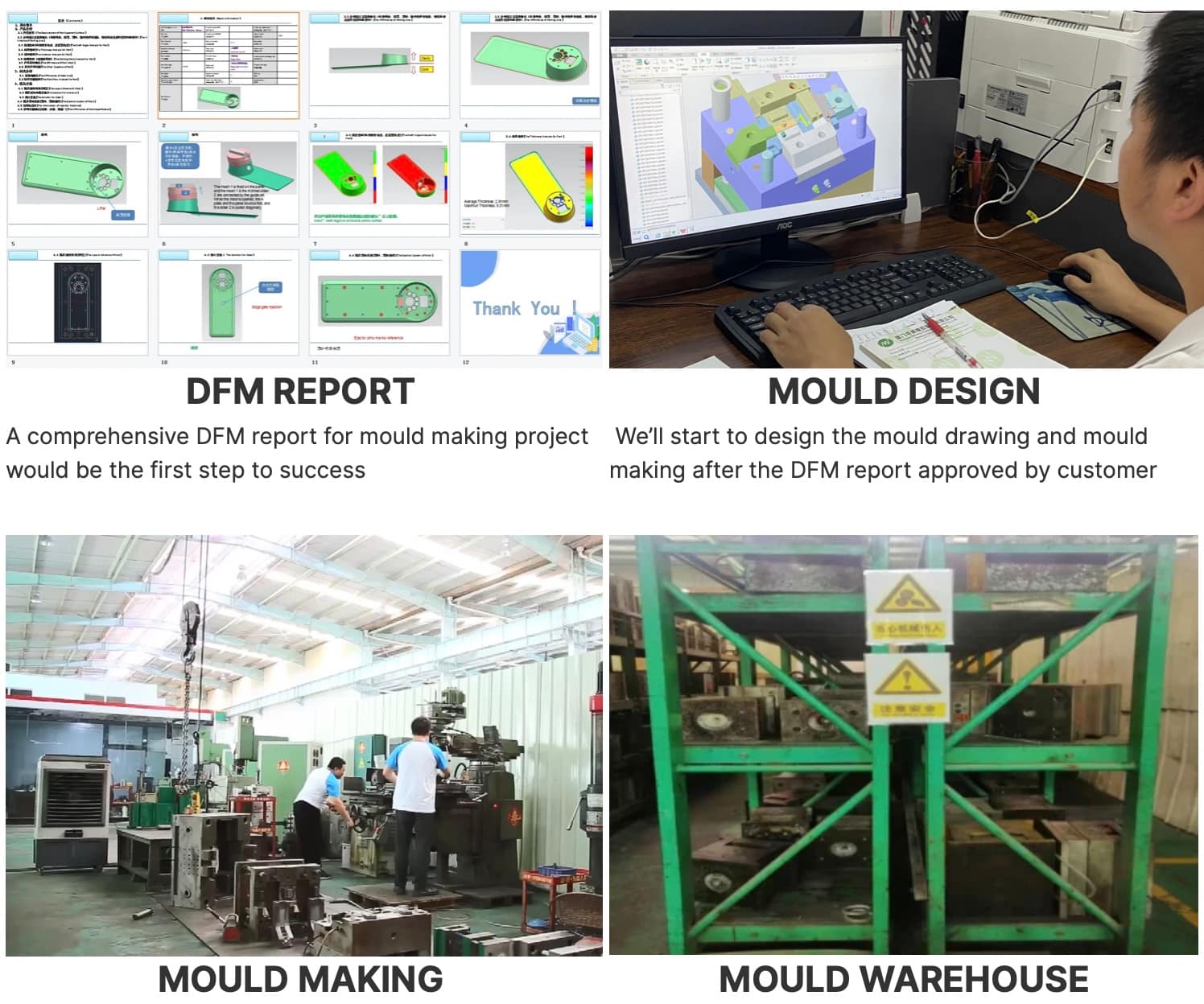

Mould Design Process:

Step 1: Analyze the product drawings

Step 2:Create the Design for Manufacturability (DFM) report

Step 3: Make the mould flow analysis

Step 4: Design tooling drawings

Step 5: Mould making

Surface Treatment

QC