XIAMEN SENGKEN INDUSTRY&TRADE CO.,LTD.

Custom high quality mould for injection molding machine 3d design Wire Terminal Connector plastic injection mold

Custom high quality mould for injection molding machine 3d design Wire Terminal Connector plastic injection mold

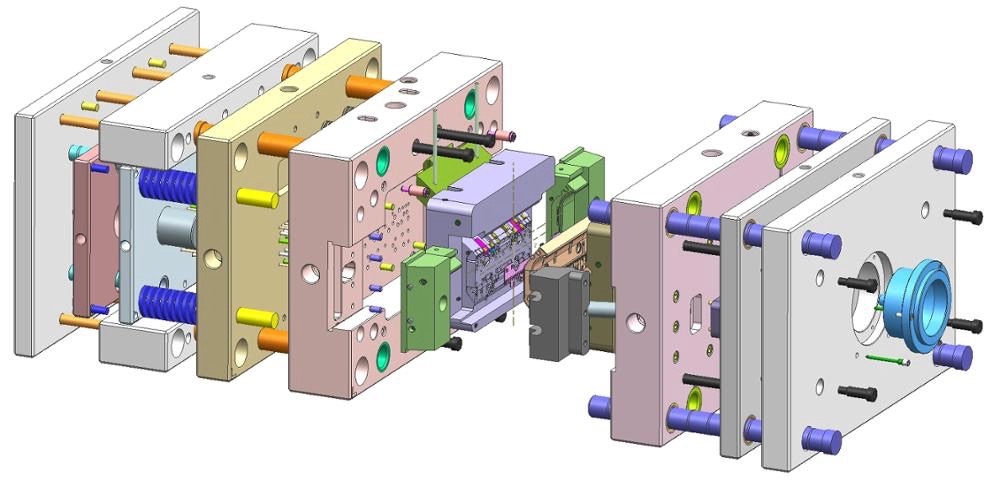

Product Name :

injection molding machine 3d designShaping Mode :

Plastic Injection MouldCore & Cavity Steel :

2316# steel, S136, H13,718,SKD61,P20,S50C,45#steel,4Cr13, 3Cr13, Becu or based on customer's requiretMould Base & Standard Component :

P20, 4cr13, h13Steel Hardness :

HRC30-35 for base material; HRC45-48 for core and cavity material; HRC60-62 for special parts materialMoud Precision :

+/-0.01mmCavity Number :

Single cavity, multi-cavity, and family mouldsRunner :

Hot Runner / Cold RunnerProduct Name: Custom high quality mould for injection molding machine 3d design Wire Terminal Connector plastic injection mold

Shaping Mode:Plastic Injection Mould

Core & Cavity Steel: 2316# steel, S136, H13,718,SKD61,P20,S50C,45#steel,4Cr13, 3Cr13, Becu or based on customer's requiret

Mould base & Standard Component: P20, 4cr13, h13

Steel Hardness: HRC30-35 for base material; HRC45-48 for core and cavity material; HRC60-62 for special parts material

Plastic Material: ABS/PP/POM/TPU/TPE/PC/PA6/PA66/PC+ABS/PA6+GF/HIPS/PE/PVC etc.

Moud Precision:+/-0.01mm

Cavity Number: Single cavity, multi-cavity, and family moulds

Runner: Hot Runner / Cold Runner

Injection System: Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc.

Equipment: CNC,EDM, 3d coordinate measuring instrument,Machine,plastic machinery,etc

Surface Treatment: Polishing,Painting,Chroming,Anodizing, Brushing, Silk Screening,Water Transfering, Laser Cutting,Leather Covering,Texture,Sanblasting,Gilding,UV Painting…

Ejector System: Unscrew by motor, stripper plate, ejector sleeve, ejector pin

Lead Time:

-Tooling: 10-45 days;

-Sample: 3 days;

-Production time : 10-30 days

Product Photos:

INSERT MOLDING:

Insert molding is a custom injection molding process that encapsulates components in a plastic part. It is commonly used for plastic injection molded parts with molded-in metal features, such at strengthening members and threaded inserts.

OVERMOLDING:

Overmolding is a unique injection molding process that combines two or more components together.It is the best practice for the plastic manufacturing of multicolor and multi-layers products.

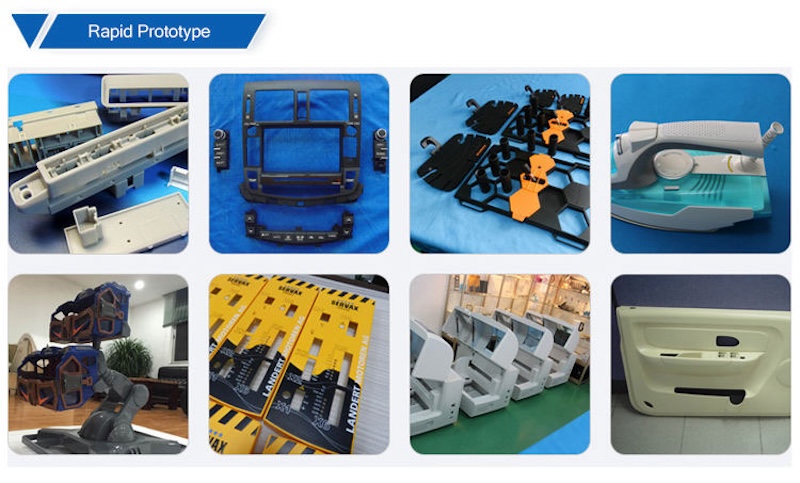

PROTOTYPE TOOLING:

Fast and cost-effective process to create aluminum or steel injection molds for quick turn injection molding.Ideal for rapid prototyping needs or validating product concept for production.

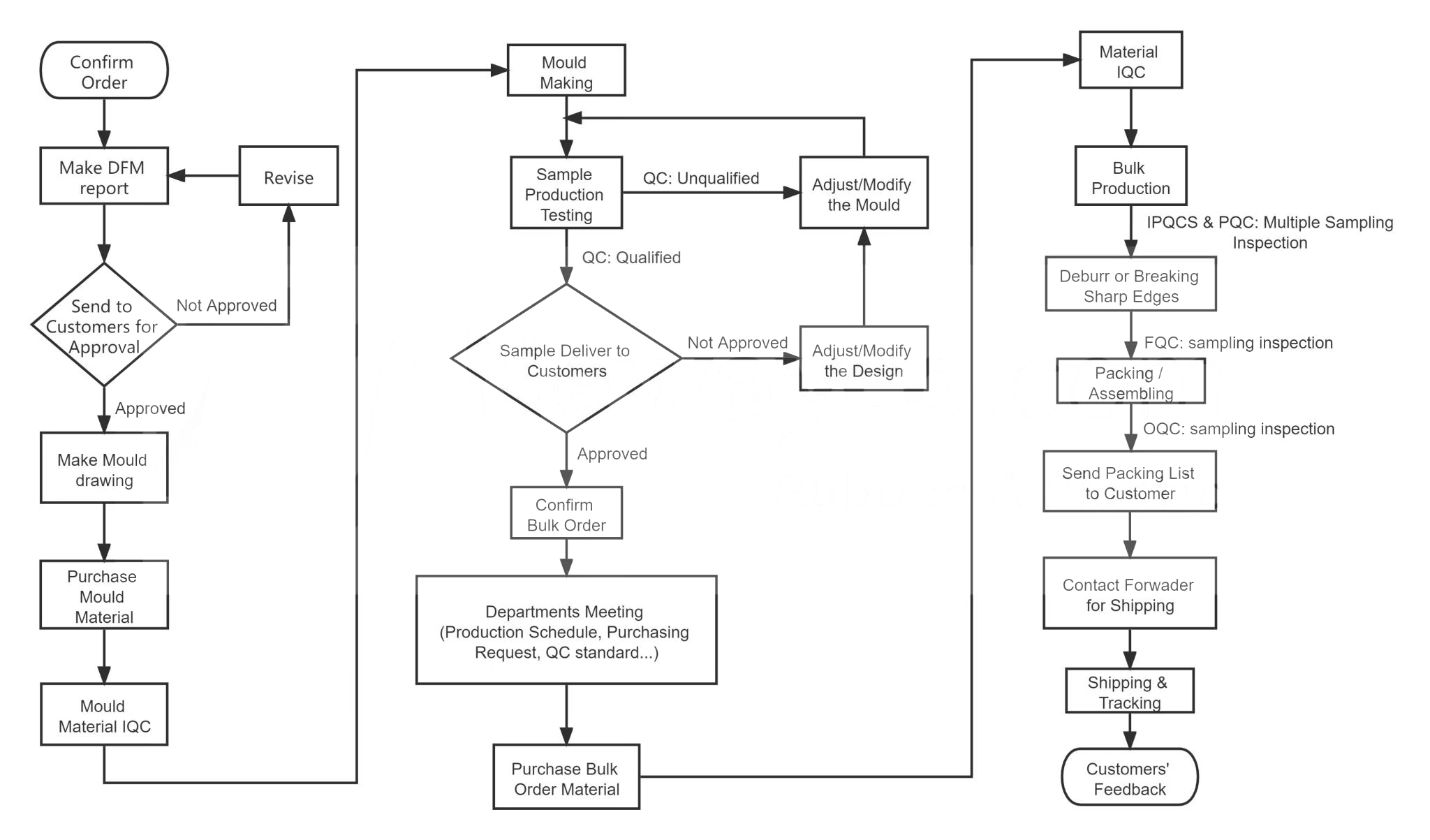

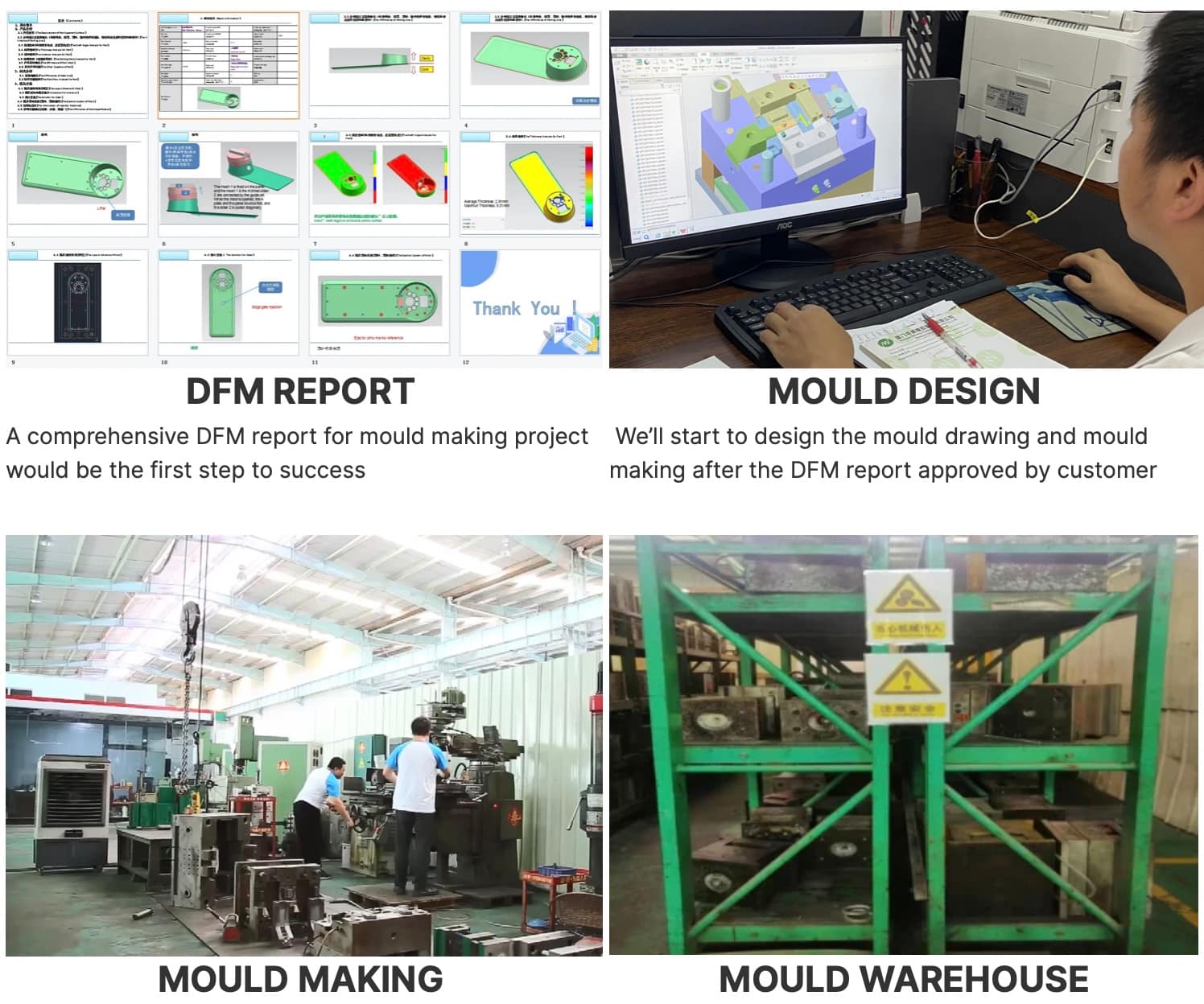

Mould Design Process:

Step 1: Analyze the product drawings

Step 2:Create the Design for Manufacturability (DFM) report

Step 3: Make the mould flow analysis

Step 4: Design tooling drawings

Step 5: Mould making

Surface Treatment

QC