XIAMEN SENGKEN INDUSTRY&TRADE CO.,LTD.

Injection Molding

We supply Plastic Injection Production service and Secondary Process-if necessary(ultrasonic welding,silk screen,hot-melting….)

Injection moulded parts can have custom finishing, polishes, or surface textures.

-Injection Moulding, Insert Moulding / Embedding Molding, Overmoulding / Secondary Molding

-Single cavity mold, Multi cavity mold, and Family moulds / one mold multi casting mold

-Plastics, Resins

-Ideal for serial production of plastic parts

-Rapid tool production in up to 2 weeks

Injection Moulding Materials

1. Rigid Plastics:

ABS

Acrylic

HDPE

Nylon 6 / PA 6

Nylon 66 / Nylon 6/6

PBT

PC (Polycarbonate)

PC-ABS Polycarbonate

PC-PBT

PEEK

PEI (Ultem)

PET

PLA

Polyethylene (PE)

Polypropylene (PP)

Polystyrene (PS)

POM / Delrin acetal

PPE-PS

PPS

PSU

2. Flexible Plastics:

LDPE

3.Elastomers & Synthetic Rubbers:

PVC

TPE (Elastomer)

TPV (rubber)

Injection Molding Finishing Options

1.Maintains post-processing condition: Injection molded parts can leave visible tooling marks.

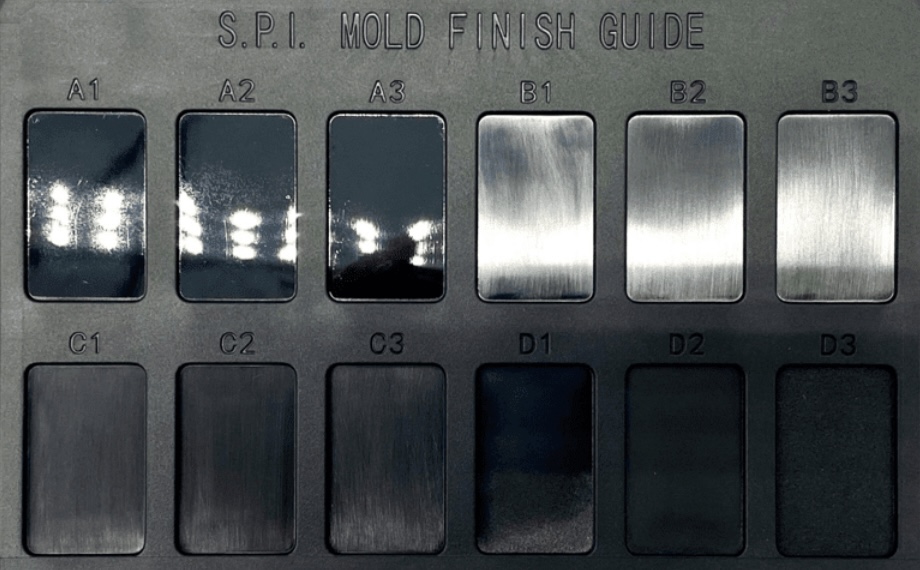

2.SPI surface treatment:

A1: Diamond – Polishing Level 3 (Highly Polished)

A2: Diamond – Polish Level 6 (Highly Polished)

A3: Diamond – Polish Level 15 (Highly Polished)

B1: Sandpaper 600 (medium polishing)

B2: Sandpaper 400 (medium polish)

B3: Sandpaper 320 (medium to low polish)

C1: Stone 600 (low polish)

C2: Stone 400 (low polish)

C3: Stone 320 (low polish)

D1: dry sand blasting glass beads

D2: Dry Blast 240 Oxide

D3: Dry Blast 24 Oxide

3.EDM STD surface treatment:

VDI 12

VDI 15

VDI 18

VDI 21

VDI 24

VDI 27

VDI 30

VDI 33

VDI 36

VDI 39

VDI 42

VDI 45