XIAMEN SENGKEN INDUSTRY&TRADE CO.,LTD.

Injection moulding is the most cost-effective way to make a plastic part at scale and offers consistent quality for low-to-high volume manufacturing. We offers a vast number of rigid plastics and resins that meet required structural and cosmetic characteristics. Beyond materials, injection moulded parts can have custom finishing, polishes, or surface textures. We offers both high-precision tool manufacturing and injection moulding services.

Our Injection Molding Capabilities:

1.Capabilities: Injection Moulding, Insert Moulding, Overmoulding;

2.Lead Time: Starts at 10 business days;

3.Tooling:

Rapid Tooling: Recommended for 100-10000 parts;

Production Tooling: Recommended for over 10000 parts;

4.Materials: Plastics and resins;

5.Machines Available: Single cavity, multi-cavity, and family moulds; 50 to 1650+ press tonnage; side actions including hand-loaded cores;

6.Mould Cavity Tolerances: ±0.1mm when machining the mold and an additional ±0.05mm when calculating for shrink rate;

7.Part to Part Repeatability: ±0.1mm or less

8.Critical Feature Tolerances: Tighter tolerances can be requested and may increase the cost of tooling because of additional sampling and grooming.We will mill to a steel-safe condition on critical features.

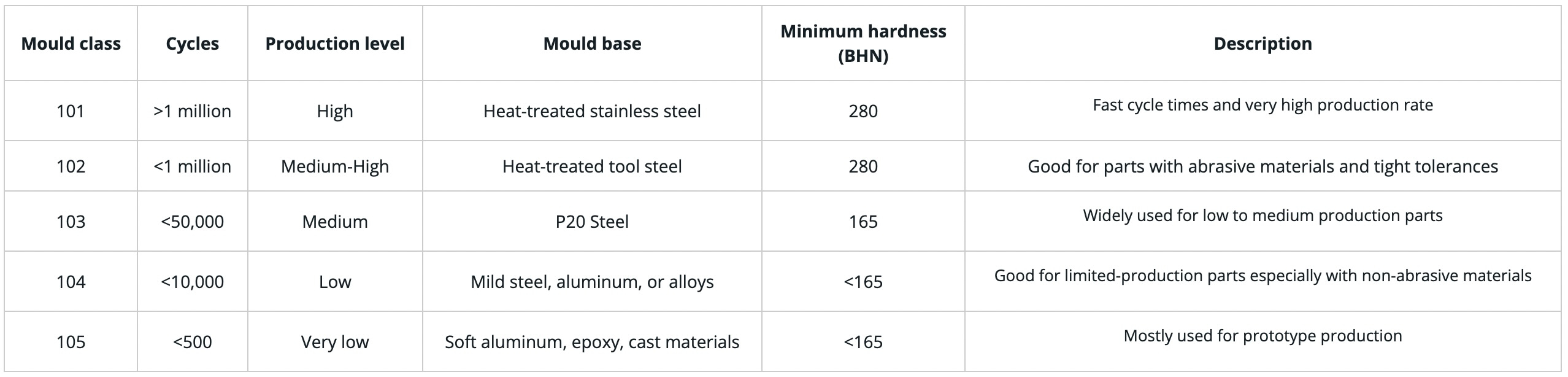

9.Available Mould Types: Steel(tool steel,carbon steel) and aluminum;Production grades range from class 105 (a prototype mold) to Class 101 (an extremely high production mould);

Advantages of Injection Moulding:

1.Rapid Turnaround: We offer fast mould lead times: in as fast as 10 business days for rapid tooling and up to 20 days for production tooling.

2.Serial Production: Ideal for the production starting from 100 parts.

3.Precision: We offers tight tolerance options in accordance with ISO 16742, up to ±0,07 mm depending on the precision of the mould and size of the parts.

4.Tooling: Single, multi-cavity, and family mould options.

5.Material Selection: Vast materials selection allows you to get the desired strength and surface quality.

6.Quality Control: Our QA department performs strong quality assurance.

Injection Moulding Mould Classes