XIAMEN SENGKEN INDUSTRY&TRADE CO.,LTD.

Custom Plastic PVC Silicone Resin High Quality CNC SLA SLS 3D Printing Rapid Prototype Service

Custom Plastic PVC Silicone Resin High Quality CNC SLA SLS 3D Printing Rapid Prototype Service

Product Name :

Custom Plastic PVC Silicone Resin High Quality CNC SLA SLS 3D Printing Rapid Prototype ServiceShaping Mode :

Plastic Injection MouldCore & Cavity Steel :

2316# steel, S136, H13,718,SKD61,P20,S50C,45#steel,4Cr13, 3Cr13, Becu or based on customer's requiretMould Base & Standard Component :

P20, 4cr13, h13Steel Hardness :

HRC30-35 for base material; HRC45-48 for core and cavity material; HRC60-62 for special parts materialMoud Precision :

+/-0.01mmCavity Number :

Single cavity, multi-cavity, and family mouldsRunner :

Hot Runner / Cold RunnerWe provide 3D printing services for the production of both prototypes and series of parts in as fast as 3 days. We have the capability to produce parts by Stereolithography(SLA), Selective Laser Sintering (SLS), HP Multi Jet Fusion (MJF), Fused Deposition Modeling (FDM), Selective Laser Melting (SLM).

Product Name:Custom Plastic PVC Silicone Resin High Quality CNC SLA SLS 3D Printing Rapid Prototype Service

Materials:Custom Machine Shop Router Lathe Precision 3D Brass Stainless Steel Aluminum Milling Turning Parts CNC Machining Service

1. Rigid Plastics:

ABS / ABS-ESD7 / ABS M30 / ABS SL7820 / ASA / CE 221 (Cynate Ester) / DPR 10 / EPX 82 (Epoxy) / FPU 50 (Flexible Polyurethane) / Nylon 12 Carbon-Filled / Nylon PA11 / Nylon PA12 / Nylon PA12 Glass-Filled / PC-ABS Polycarbonate / PC-ISO Polycarbonate / PC-like Heat Resist Translucent / PC-Polycarbonate / PLA / PETG / PEEK / PP Polypropylene / RPU 70 (Rigid Polyurethane) / ULTEM 1010 High-performance thermoplastics / ULTEM 9085 High-performance thermoplastics / UMA 90 (Urethane Methacrylate) / Watershed XC 11122 ABS/PBT-like / Xtreme Grey Polypropylene/ ABS-like / Xtreme White 200 Polypropylene/ ABS-like

2. Flexible Plastics:

Flex Whitish TPU/TPE-like

Estane TPU M95

3. Rubber-Like Plastics:

Elastomeric Polyurethane (EPU 40)

SIL 30 (Silicone)

4. Silicone Rubber:

True Silicone

5. Metals:

• Aluminum (6061/7075/6063/5052/2A12 ,etc.)

• Brass (C36000(C26800) C37700(HPb59) C38500(HPb58) C27200(CuZn37) C28000 ,etc.)

• Copper

• Steel(20# 45# Q235/A3 40Cr,etc.)

• Stainless Steel(302/303/304/316/310/420,etc.)

• Iron (1213/12L14/1215,etc.)

• Bronze (C51000/C521000/C54400,etc.)

• Magnesium

• Zinc

• Titanium

• Carbon Fiber ,etc.

6. Photopolymer:

Rigid Photopolymer (Black, Grey, White)

Surface Treatment:

1.Metal: Polishing/ Fibre Drawing/ Anodizing/ Powder Coating/ Silk-Screen/ Electroplating/ Laser Engraving/ Passivating etc.

2.Plastic: Painting:Matt/ Texture/ Polishing/ UV Painting/ Rubberizing;

Silk-Screen/ Electroplating etc.

Tolerance: +/-0.01mm ot +/-0.05mm

Available Format: igs/.stp/.x_t/.step/.prt/.stl/.sldprt/.dwg/.dxf

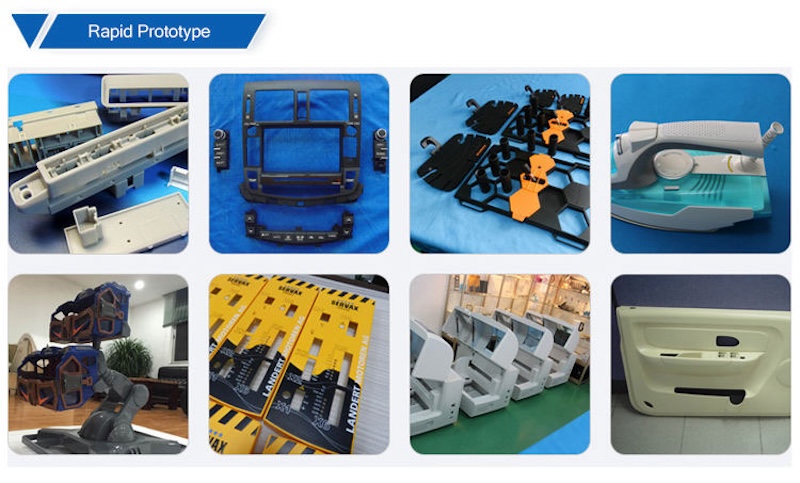

Some Popular Processes for Prototypes:

1. 3D printing, there are some popular process, such as SLA, FDM, SLS, FFF.

2. Vacuum Casting. The material is more stronger than the SLA process.

3. CNC machining, the material can be same as the future mass production, which can save the mould cost.

4. Sample Mould with 1 Cavity.

Our Services:

1.SLA & SLS 3D Printing

2.Silicone Mold&Vacuum Casting

3.CNC Plastic Machining

4.CNC Metal Machining

5.Plastic Injection Moulding

6.Die Casting

7.Sheet Metal Fabrication ,etc.

We Can Also Provide Mould Spare Parts Export, eg: Slider, Inserts, Ejector Pins, etc.

Service Fields:

1.Medical Device

2.Automotive

3.Intelligent Robot

4.Home Appliances

5.Office Equipment

6.Consumer Electronics

7.Other Industries ,etc.

We has complete production chain from R&D, Rapid Prototypes, mould design, mould making, components production, assembling, packing to export.

The most common used surface treatment are: Matte, Texture (fine texture, rough texture...), Common Polishing, Mirror Polishing, Laser Engraving, Printing, Plating, Brushing, Marbling), etc. You can view below surface pictures for reference:

We highly welcome custom surface treatment for injection molding plastic parts.

Our plastic parts prototypes quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.We dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

All our materials are purchased from certified suppliers. All materials will be subject to warehousing quality inspection upon arrival. After the pre-production sample is confirmed, the sample will be sealed immediately. prenatal sampling inspection, intrapartum sampling inspection, and postpartum sampling inspection, and the inspection results will be recorded in time. All files are traceable.

Product Photos

Surface Treatment

QC